Application Examples

LEARN MORE

Facial Recognition

Facial recognition is a biometric software application capable of uniquely identifying or verifying a person by comparing and analyzing patterns based on the person’s facial contours. Facial recognition is mostly used for security purposes, though there is increasing interest in other areas of use. Pleora Technologies product application example below!

Pleora Solutions

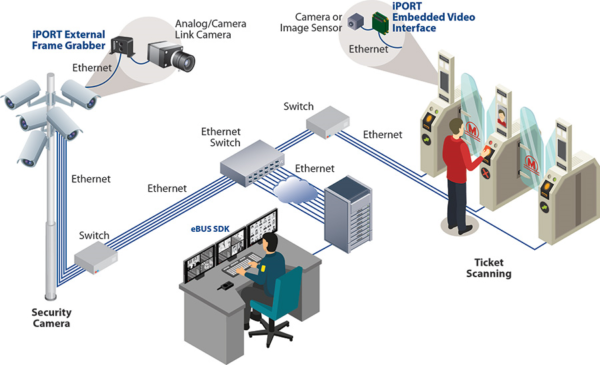

Pleora’s external frame grabbers convert image feeds from roadside analog and Camera Link cameras into GigE Vision video. Uncompressed image feeds from multiple cameras are streamed with low latency over the extended-reach Ethernet network to a central office for automated processing and display. The external frame grabbers’ integrated programmable logic controller (PLC) synchronizes sensors and lighting sources and triggers the image acquisition process.

Businesses, transportation systems, and government offices are also using facial recognition to verify identification and screen individuals. In these systems, existing legacy cameras are converted into GigE Vision devices by Pleora’s external frame grabbers. Alternatively, designers can speed the design of GigE Vision imaging devices with Pleora’s GigE Vision embedded video interfaces. With the video output from all cameras and image sources converted into a common format, designers can create a real-time networked imaging system integrating existing and new imaging sources. Using Pleora’s eBUS SDK software, end-users can manage and control the multi-vendor end-to-end imaging system.

Quality Inspection

Quality control is the set of measures and procedures to follow in order to ensure that the quality of a product is maintained and improved against a set of benchmarks and that any errors encountered are either eliminated or reduced. The focus of quality control is to ensure that the product and product manufacturing are not only consistent but also in line with customer requirements. Euresys product application example below!

Euresys Solutions

Line-scan image acquisition for surface inspection machines:

The Coaxlink and Grablink cards are dependable industrial frame grabbers that provide robust and stable image acquisition from the fastest digital cameras available. They feature precise line-scan camera control and synchronization functions.

Line-scan image acquisition for textile inspection:

The Coaxlink and Grablink cards are dependable industrial frame grabbers that provide robust and stable image acquisition from the fastest digital cameras available. They feature precise line-scan camera control and synchronization functions.

Low-cost image acquisition from industrial analog cameras for inspection machines:

Take advantage of the lowest-cost industrial cameras available on the market with the Domino and Picolo series cards

High-speed image acquisition for AOI, 3D SPI, 3D lead/ball inspection machines:

The Coaxlink and Grablink cards are dependable industrial frame grabbers that provide robust and stable image acquisition from the fastest digital cameras available. They feature precise camera control and synchronization functions.

– AOI (Automated Optical Inspection) machines

– 3D SPI (Solder Paste Inspection) machines

– 3D lead/ball inspection machines

Microscopy

The examination of minute objects by means of a microscope, an instrument that provides an enlarged image of an object not visible with the naked eye. TRU-Vu Monitors & Imperx product application examples below!

Tru-Vu Solutions

Modern video imaging and inspection microscopes are increasingly replacing eyepieces with digital video cameras and high-resolution LCD monitors. TRU-Vu Monitors’ razor-sharp images and superb color reproduction enable operators to detect abnormalities, problems, and defects that previously may have gone unnoticed. Our 21.5″ to 42″ monitors can display both analog and digital video microscope images, up to full 1920×1080 HD resolution. Our wide 178º viewing angles enable several users to view the images simultaneously.

Imperx Solutions

Programmable Flexibility

Imperx Medical cameras provide selectable binning modes up to 8x independent vertical and horizontal. Our Medical cameras also offer up to 7 ROIs for data reduction or faster readout. The exposure time is easily programmable in 1-microsecond increments.

Imaging Control

Imperx Medical cameras feature an optimal design focused on sensor performance. Our Medical cameras feature pre-amplifier gain control, standard gain amplifier control from 0 to 36dB in 1024 steps, and up to 3x digital gain control to provide the greatest signal enhancements with the lowest noise possible.

Color Sensitivity

Imperx Medical cameras provide several sensor options for color sensitivity. For standard low light sensitivity, Imperx has an array of EXview HAD sensors from Sony with the sensitivity of .2 LUX. Our Medical cameras also support the Sparse CFA line of sensors from TRUESENSE which offers 2x to 4x the light sensitivity compared to standard Bayer pattern color sensors.

Horticulture

The science and art of producing, improving, marketing, and using fruits, vegetables, flowers, and ornamental plants. It differs from botany and other plant sciences in that horticulture incorporates both science and aesthetics. Metaphase Technologies product application example below!

Metaphase Solutions

IRD Poultry Light:

Metaphase has developed an LED spectrum that lends itself to poultry applications. The light does not disrupt current hen laying egg production; significantly reduces or in some cases eliminates parasitic mites from poultry; and spurs non-laying hens to start laying eggs… even in winter. This fixture carries both a UL label and an EPA label. The EPA label affords Metaphase the authorization to manufacture insect repellent devices. There are no chemical pesticides necessary for use with the light… presenting itself as an “organic” solution. The IRD Poultry Light may reduce pecking and cannibalism… testing is being done to verify.